Wire and spark erosion manufacturing specialist EDM Precision Technologies has reported another year of growth after investing in over half a million pounds of machines at its Silverstone Park premises.

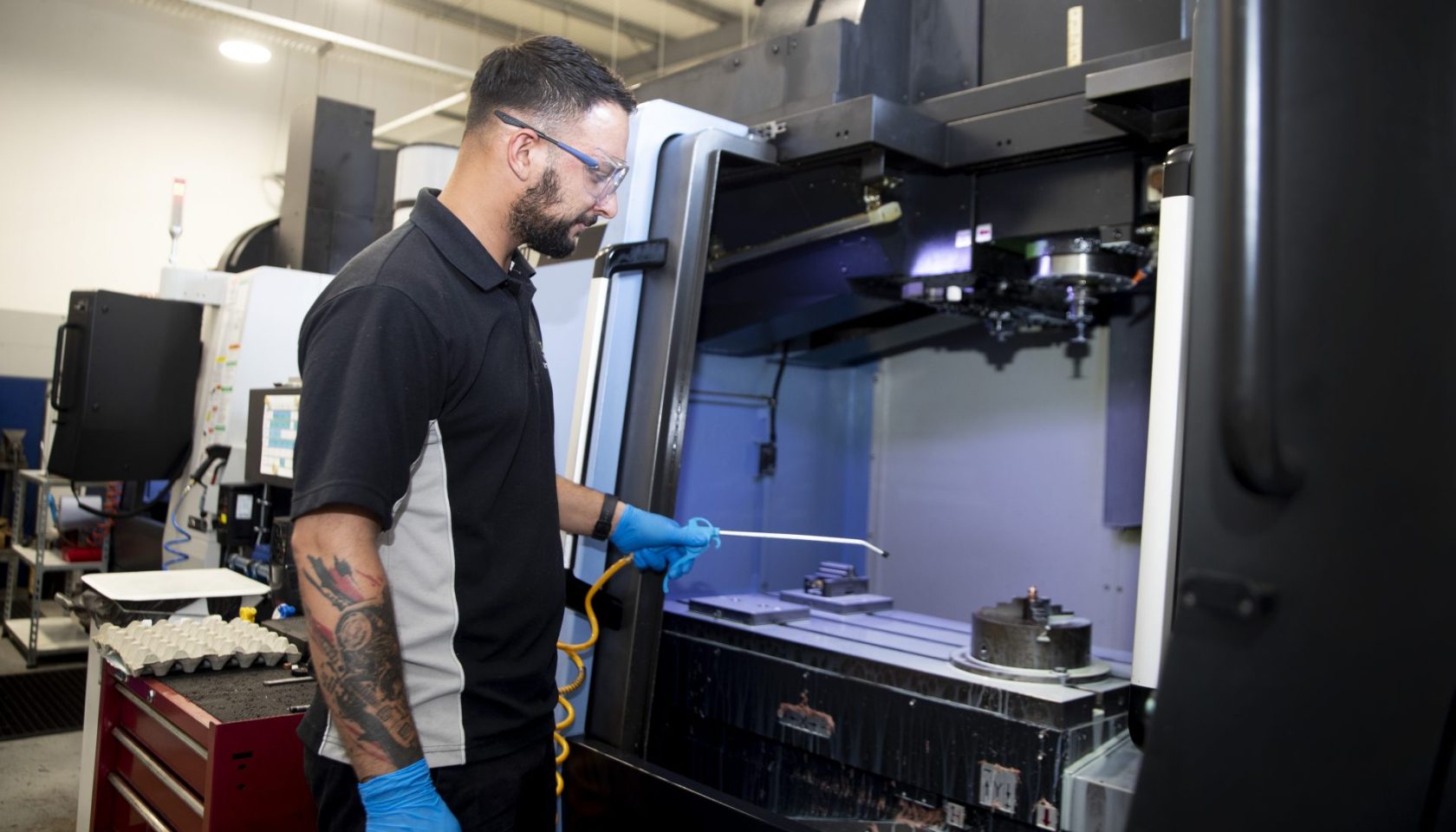

The business has recently taken delivery of a second Doosan DN Solutions DNM4500 high performance CNC mill.

MD Paul Waldron explained:

“This now works in tandem with its sister machine which helps with ‘through-put’. Our work is now interchangeable between the two which increases efficiency.

“The carousel of 30 cutting tools included with the machine is very impressive – this automatically and quickly selects which tool is required for which part of the programme, including a probe which helps find the centre or edge of a part before machining.

“The precision is incredible – we’re down to ten microns (0.010mm) and maybe even less on smaller componentry.”

Whilst a lot of EDM’s work continues to be for motorsport, it also successfully provides its services to other sectors including aerospace, defence, medical, scientific equipment and research.

“We get asked to do a lot of sample preparation for material testing laboratories by many of the big universities who are in partnerships with industry,” continued Paul.

“In the last four years we’ve replaced seven machines and spent £550,000, and we have also just placed a new order for a new wire erosion machine at £100,000 which will arrive in August.

It’s part of our continuing investment of replacing old with new – we find that machines are getting better with even greater accuracy, reliability and speed.

Demand for EDM’s services meant, against the odds during the Covid-19 pandemic, that it enjoyed one of the strongest periods in its near 30-year history.

Paul added: “That growth has continued – 2022 was another record-breaking year and we’re on course to better that again this year.

“Yes, our costs and prices have increased but customers are accepting that is the real world as they are seeing it in their personal lives.

“I believe that what makes us unique is that we can produce something of very high accuracy and precision quickly.

“And whilst we’re a relatively small business, we have very good people and machines which means we are extremely agile – we can make decisions very quickly and adapt to our customers’ demands.

“In addition to building a really good customer base, we’ve also developed a very good chain of suppliers which is vital.”